- Can 3D print solid models or watertight meshes only (Watertight: a closed model with no openings or loosely joined edges)

- AutoCAD does not support 3D printing of colors or materials

- 3D printed parts have limitations on minimum wall and shell thickness (Check with vendor)

- Determine the correct amount of clearance required for moving parts (Check with vendor)

- If a complex model gives errors during 3D Print, manually union the individual objects together one at a time, and retry 3D Print

- Preview window will help to determine if the model will print correctly. Expand the 3D Printing Pane preview to ensure all selected objects are present

Sunday, June 6, 2010

Guidelines for 3D Printing

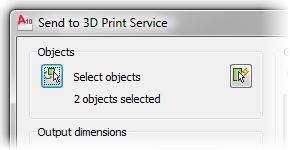

Send 3D Print to Service

1. Output tab > 3D Print panel > Send to 3D Print Service

2. 3D Printing dialog box > Continue

3. Select the objects to send. They must be solids or watertight (closed) meshes

4. Choose to add more objects to the selection set or use the Quick Select panel to create a selection set filter

5. Change the scale or the output dimensions of the model

6. Use the preview window to verify what will be printed ( not reflect the edit changes)

7. Choose a location and file name for the ST file

8. Browser will open and link to the Autodesk 3D Printing web page. Review all vendors and select one that meets the needs

3D Printing in Industrial

3D Printing can be used in many imaginative 想象的 ways:

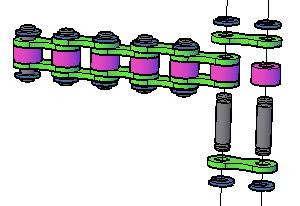

Assemblies

For manufacturing applications, in one run can build a working model with multiple moving parts

All the parts can be created at one time using one STL file

No assembly is required

Tooling

Create a mold using 3D printing

Architecture

Create a complete mockup 实体模型 of a building with fixtures, doors, and even furniture if desired

Create a separate roof that can be removed

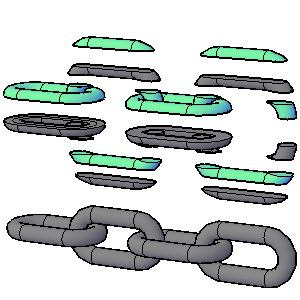

How 3D Printing Works

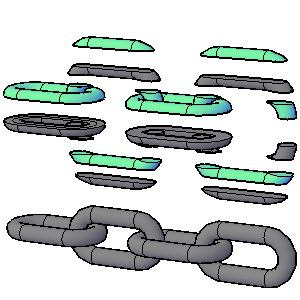

When convert the 3D model into an STL file, it digitally slice it into many thin section views

The STL machine creates a thin layer of plastic that is dimensionally accurate in shape and size to each section view

It creates each layer in the proper order and permanently attaches it to the previous layer

Several components of an assembly can be made in place at the same time

Multiple pieces can be created in successive layers to create a moving assembly

3D Printing

Output tab > 3D Print panel > Send to 3D Print Service

3D Printing is a process that include several types of rapid prototyping technology

Stereolithography 立体平版印刷 (commonly abbreviated to STL or SLA) is the technical term for one process that enables to create plastic 3D models directly from AutoCAD composite solid or mesh models

The original file remains intact 完整无缺 and a new file is created with the extension .stl

The new file is imported into a stereolithography machine which creates the physical model

Saturday, June 5, 2010

Digital Prototype

In some cases having a physical model that can touch and examine, can provide additional insight to the design and assist in presenting that design to others

3D Printing enables to create a physical, scaled prototype of your design that is both cost effective and easy to produce

Finding errors or envisioning ergonomic 人类环境改造学的 improvements before committing to expensive production tooling can prevent costly changes

Create a Recorded Walk

1. Exercise thumbnail > Play > New Shot

2. New View / Shot Properties dialog box:

- View name: enter walk to kitchen

- View category: select Exercise

- View type: select Recorded Walk

- Transition type: select Cut to shot

- Click Start Recording

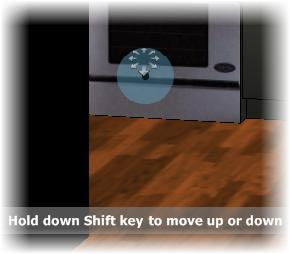

3. Use the Walk controls to create a short recording:

- Move the cursor over the door of the stove before you click

- Hold the mouse button down. Move the cursor further from the control point, will faster the movement

- Release the mouse button to stop recording

- Click Preview to review the recorded walk

- If necessary, repeat steps 2 and 3 to rerecord the Walk

- Click OK

4. Review your cinematic shot sequence

Status bar > Show Motion

Exercise thumbnail > Play

Subscribe to:

Comments (Atom)